What Is A Centrifugal Clutch?

A centrifugal clutch is a mechanical device which is used on driven rotary equipment. Most commonly used with a combustion engine, the clutch can be used to automatically transmit the torque from the drive to the driven equipment giving a “soft start” with no load engagement. By using this type of clutch between the drive and the driven equipment the speed at which the mechanical driven shaft engages can be controlled. As the engine speed is increased to or above the set engagement speed of the centrifugal clutch the mechanical drive will become engaged. This enables the operator to run the engine at a designated idling speed without driving the equipment, thus allowing the engine to reach its optimal torque before experiencing load.

What Are The Advantages And Disadvantages Of Using A Centrifugal Clutch?

Using a centrifugal clutch on engine driven equipment enables the engine to be started under a no-load situation. When the engine is idling the drive remains disengaged. Only when the rpm of the engine is increased to the set engagement speed of the clutch or above will the drive be fully connected. This results in a smooth engagement and prevents the engine from stalling. It also helps protect the engine by ensuring high levels of torque are not transmitted back through the flywheel of the engine. In circumstances such as this, for example when the rotating equipment is for some reason jammed, the extreme levels of torque transmitted back through the engine can cause significant and in some cases irreparable damage to the engine. This can be a very costly and sometimes economically unfeasible to repair the equipment. By using a centrifugal clutch, this can be avoided as the components of the clutch will take the overload. The wearing parts of a clutch are easy and cost effective to replace. In addition to providing a no-load situation the set engagement speed of the clutch also allows the operator to control at what point the rotary equipment becomes engaged. This allows the engine of the machinery to be running but without necessarily operating.

Due to the nature of centrifugal clutch being a purely mechanical automatic engagement at a pre-determined speed, each application may require a specific configuration. Meaning this pre-set engagement speed cannot be changed without altering internal components.

How Does A Centrifugal Clutch Work?

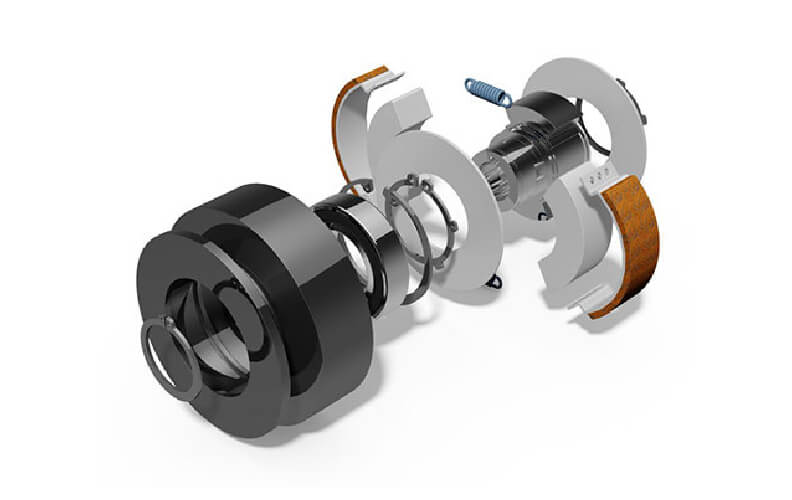

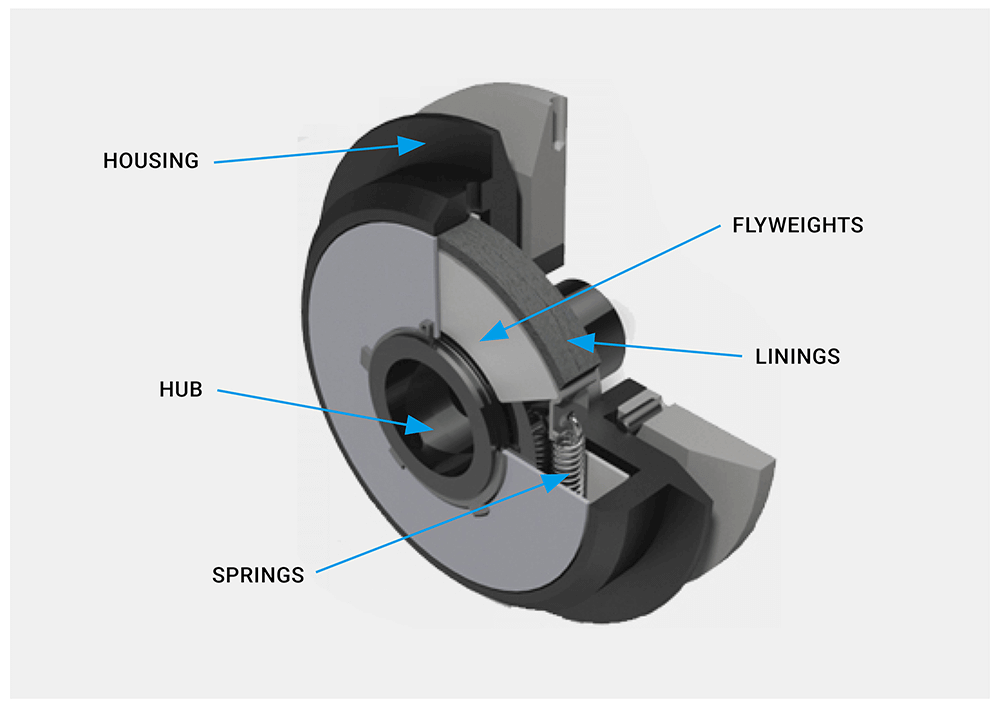

A centrifugal clutch works, as the name suggests, through centrifugal force. The key components of a centrifugal clutch are the hub, flyweights (clutch shoes), springs, linings and housing (shown in the diagram below). The centrifugal force, created by the revolutions of the engine is transmitted through two or more flyweights. The clutch can be driven by a number of ways depending upon the design of the machinery. One of the most common methods is by mounting the clutch onto the parallel or taper crank shaft of the engine. When the crank shaft rotates the shaft of the clutch rotates at the same speed as the engine. The rotation of the hub forces the shoes or flyweights outwards until they come into contact with the clutch drum, the friction material transmits the torque from the flyweights to the drum. The drive is then connected. The springs, flyweights and the friction material are responsible for determining the speed at which the clutch engages. Depending on the design of the machine the output from the clutch can be one of a variety drives, including but not limited to shaft, pulley, sprocket or flange.

Centrifugal Clutch Applications

A centrifugal clutch can be useful for a range of engine driven equipment with a high starting inertia. They are commonly found on mobile equipment with rotating parts that are driven by small diesel or petrol engines. Some of these examples include:

- Vibratory plate compactors and rollers

- Rammers

- Compressor/vacuum/fan drives

- Trowel and concrete finishers

- Compact road/street cleaners

- Transport refrigeration units

- Mobile water pumps

- Groundcare equipment – rotary and flail mowers, turf cutters and scarifiers

- Go-karts

- Woodchippers/stump grinders/milling cutters